Self-Tapping Screws vs Self-Drilling Screws: Which One Should You Use?

Introduction

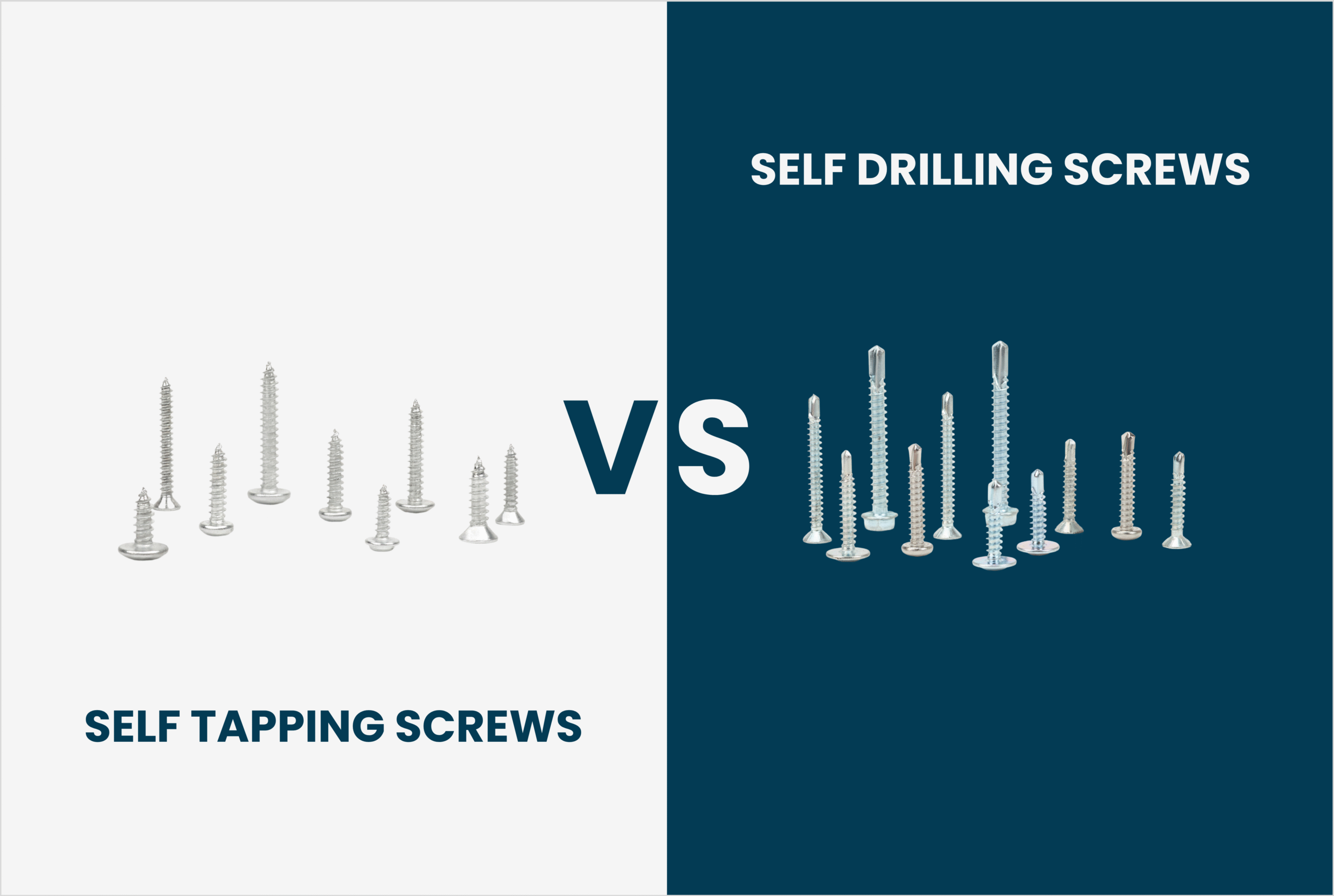

When it comes to choosing screws for any project, you will often come across two terms that seem interchangeable – self-tapping screws and self-drilling screws. At a cursory glance, they may appear to be the same, but there’s a fundamental difference between the two that results in them performing quite different jobs.

Although both of them are designed to create threads as they are driven into materials, the primary difference lies in how they prepare the hole and the amount of work required before installation. While one prioritizes precision and material control, the other concentrates on speed and convenience.

In this blog, we break down their workings, use cases, and major differences between these two screw types, allowing you to pick the right one for your project.

Self-Tapping Screws

Before you can use regular screws, you normally have to tap a separate thread. Self-tapping screws, on the other hand, may cut or create threads right into the base material as they are being put in, so there is no need for any further tapping. This makes the whole process of putting together self-tapping screws a lot easier.

Self-tapping screws are well-known and commonly utilized in factories where speed and efficiency are very important because of how they are made. They assist in making assembly line activities much more efficient by cutting down on the number of steps needed to install something. The threads are made during installation, so they fit the screw profile perfectly. This makes the grip better and lowers the risks of the screw coming away.

There are several different types of heads available in self-tapping screws, including pan head, flat head, and hex head. The sort of head type you choose depends on the application, the amount of torque that is needed, and whether the tool will work with it or not. Hex head screws may need a socket driver, although Phillips or Pozidriv heads work with regular drill bits and screwdrivers.

Self-Drilling Screws

They don’t need a separate pilot hole before installation as self-tapping screws do. The pointed head of the drill allows the screw to go straight through metal surfaces. This makes them very helpful for securing metal to metal, such as in sheet metal work, steel framing, and other similar jobs. Installation time is greatly shortened since the screw itself has a drilling function. The drill point design changes according to how thick and hard the material being secured is.

Hex head variations are often used in roofing and structural work since they let you apply more torque and hold things securely as you work. The design of the thread is also very significant for performance. Coarse threads make it easier to keep thin metal sheets together, and particular thread designs make them less likely to break when they are vibrating or under dynamic stresses.

Self-drilling screws are good for situations where there is movement or changes in the environment because they can hold their grip under stress. In general, self-drilling screws are a quick and easy way to join things together when pre-drilling would make the installation procedure longer and more complicated.

Key Differences

| Aspect | Self-Tapping Screws | Self-Drilling Screws |

| Pilot Preparation | Requires a pre-drilled pilot hole before installation | Does not require any pre-drilled hole since the screw creates its own hole during installation |

| Installation Process | Installation involves two steps, drilling and then driving the screw | Drilling and fastening happen simultaneously in a single operation |

| Speed of Assembly | Slower due to the additional drilling step involved | Quicker since the integrated drill removes the need for pre-drilling |

| Cost | Lower unit cost due to simpler manufacturing design | Higher initial cost compared to self-tapping screws |

| Labour Intensiveness | Requires more labor effort due to multiple installation steps | Requires less labor effort owing to a simplified process |

| Common Applications | Electrical enclosures, home appliances etc | Roofing sheets, metal studs, etc |

Conclusion

Self-tapping and self-drilling screws are both preferred for very different purposes, and the decision between the two largely comes down to base material being used as well as the installation process involved.

When it comes to self-tapping screws, they are much better suited for projects where the thread formation needs to be extremely precise along with a high degree of control throughout the fastening process. As such, these screws are a great option when clubbed with pilot holes in metal or plastic.

Self-drilling screws on the other hand give a lot more emphasis to speed and convenience. Thanks to their drill point, the need for pre-drilling is entirely eliminated, which makes them optimal for sheet metal, steel framing and construction applications.

Eventually, picking the right type of screw depends upon factoring in the base material, along with the installation speed and environmental exposure at play. It is important to have a thorough understanding of these variables since they play a huge role in determining the joint performance and service life of the screws.

At Fastener World (India), we offer both types of screws across different types of material grades, head styles, as well as coating options. This lets manufacturers and engineers pick the right kind of screws for their project requirements.