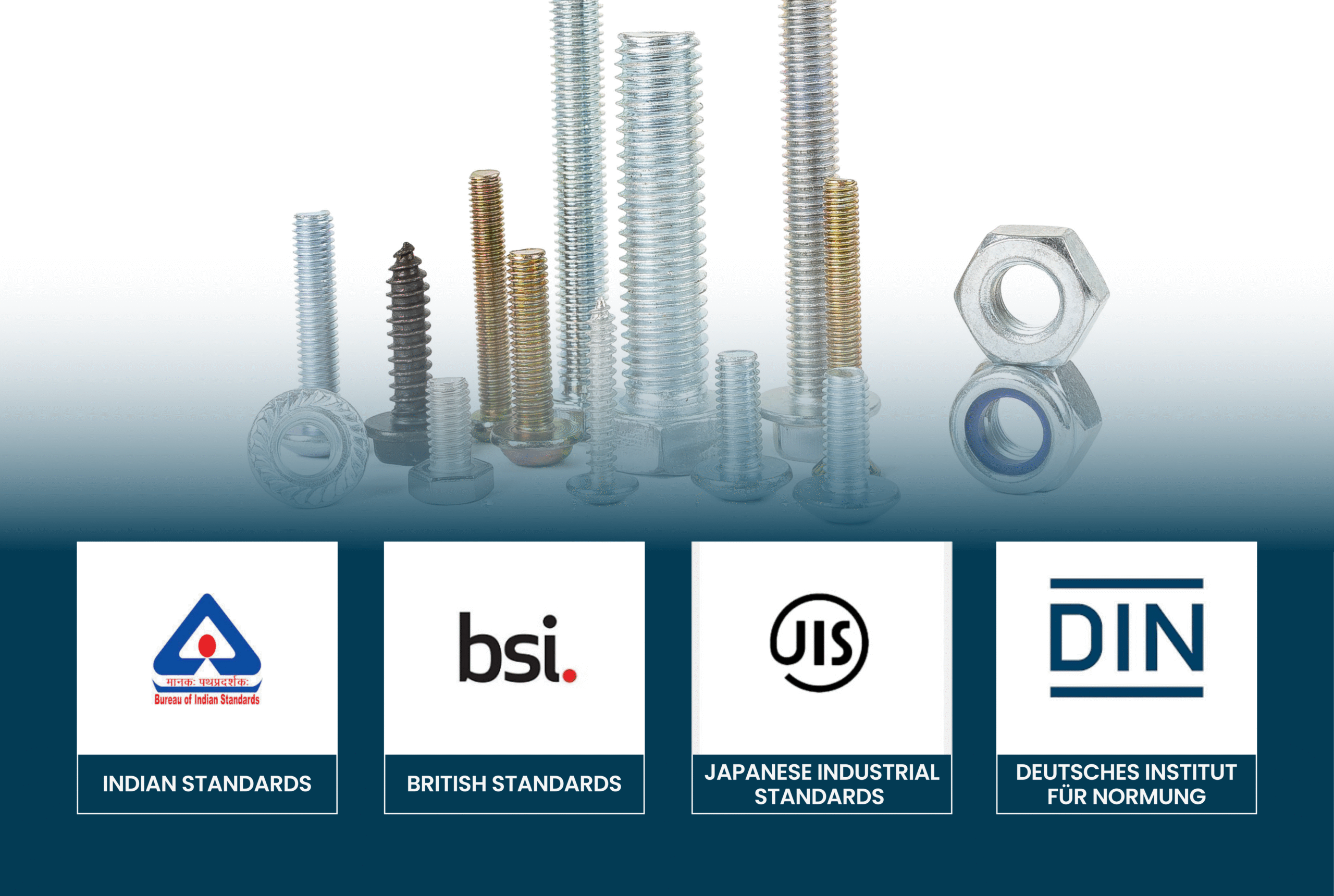

Understanding DIN, JIS, IS & BS Standards for Fasteners

Introduction

While selecting the most appropriate fasteners for your projects, the emphasis should not just be on picking the accurate size, finish, or material, it must also include a strong focus on compliance with internationally recognized standards. These standards serve as the backbone of engineering consistency, ensuring that fasteners meet specific criteria for strength, dimensional accuracy, material quality, and long-term performance.

By understanding the widely used standards, manufacturers and engineers can make more informed decisions that can go a long way in ensuring the reliability, interoperability, and safety of their final products. This standardization also simplifies procurement, reduces inventory complexity, and allows for smoother cross-border collaboration in projects involving multiple vendors.

Deutsches Institut für Normung (DIN)

DIN standards are developed by the German Institute for Standardization and are widely used across the globe. They are known for their precision and technical rigor.

They specify everything from fastener dimensions and tolerances to thread types and materials. Common examples include DIN 933, which is used for Hex Bolts, DIN 934, which is used for Hex Nuts, and DIN 912, which is used for Socket Head Cap Screws.

Japanese Industrial Standards (JIS)

JIS standards are developed by the Japanese Industrial Standards Committee, which helps define quality and dimensional consistency for fasteners used across Japan and Asia.

JIS fasteners are commonly used in electronics and automotive manufacturing, with a focus on compactness. They are typically more lightweight or compact compared to DIN standard fasteners.

Indian Standards (IS)

IS standards are developed by the Bureau of Indian Standards, catering to the specific needs of the Indian industrial and construction industry.

Certain examples include IS 1363, which is used for Hex Bolts, and IS 1367, which defines technical supply conditions. IS fasteners are mostly found in infrastructure, railways, and general fabrications.

British Standards (BS)

They were developed by the British Standards Institution and are relevant across many Commonwealth countries and legacy projects.

Even though BS standards have been replaced by ISO standards, they are still frequently used for older drawings and maintenance contracts.

Examples include BS 3692 for Precision Hex Bolts & Nuts, and BS 4190 for General Purpose Fasteners.

Conclusion

A significant amount of risk can be reduced by having an understanding of the most widely used standards related to fasteners. Doing so can ensure that the safety and quality of fasteners remain intact, even when dealing with global suppliers.

At Fastener World (India), we supply fasteners that comply with various international standards, further reinforcing our commitment to providing reliable and durable products.