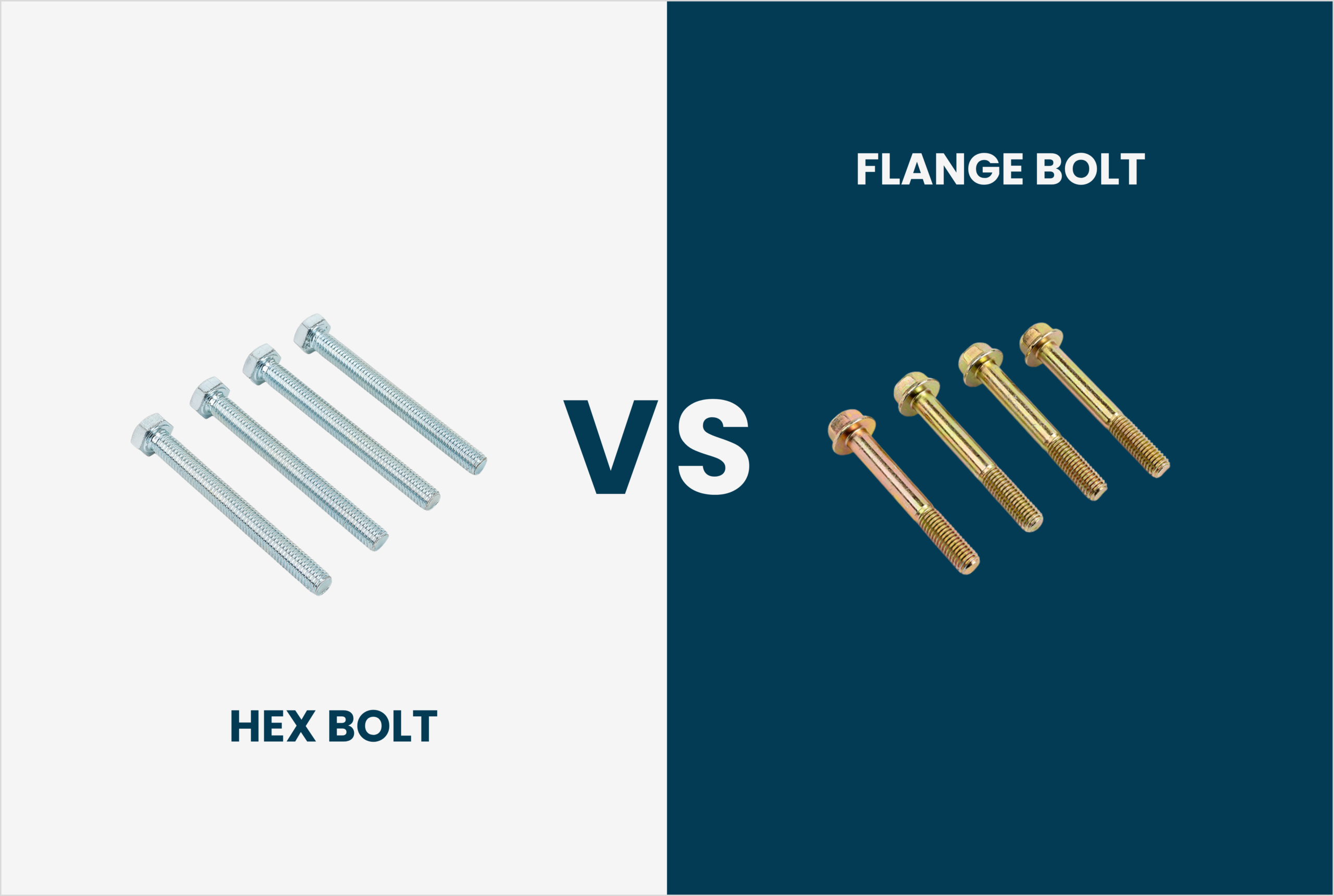

Hex Bolts vs Flange Bolts: A Practical Selection Guide

Manufacturers and engineers often look at multiple parameters like strength, assembly time and vibration resistance while assessing which bolts to use for a particular project. In many scenarios, the decision usually comes down to choosing between hex bolts and flange bolts, which are two of the most commonly used fastening options.

At the outset, both bolts seem to be quite similar, having a hexagonal head and serving comparable load-bearing capabilities. Each type excels under different conditions, and selecting the wrong one can lead to complexities during assembly, higher maintenance needs, or even premature joint failure.

In this article, we look at how hex and flange bolts work, explore their idiosyncrasies, while also outlining their key differences, assisting you to make an informed choice for your application.

Hex Bolt

Hex bolts are among the most extensively used fastening methods across applications. They have a six-sided head along with a plain bearing surface, which lets them pair with washers to get reliable clamping. This provides flexibility in selecting the washer type, based on load requirements and operating conditions.

Since they rely on external washers, hex bolts are effective in assemblies where load distribution and vibration resistance are critical.Plain washers are great when it comes to protecting mating surfaces and spreading clamping forces evenly, whereas spring washers can be added to improve joint integrity in dynamic environments. This makes hex bolts ideal for applications involving structural steel connections, heavy machinery and general industrial equipment.

At Fastener World (India), our hex bolt full thread and hex bolt half thread variants are available depending on your clamping requirements. We stock them in a wide range of material grades, including:

– Mild Steel Grades 4.6 and 5.6

– Alloy Steel Grades 8.8, 10.9, and 12.9

– Stainless Steel Grades 202, 304, and 316, routinely used in stainless steel hex bolt applications

Hex bolts are supplied in passivation options like black oxide, zinc plating and hot dip galvanization, which makes hex bolts a great option for both indoor and outdoor applications. Coating is done to enhance a bolt’s durability and also improve corrosion resistance. Material grade, size and passivation play an important role in ascertaining the hex bolt price.

Flange Bolt

Flange bolts come with a built-in washer beneath the hexagonal head which is used to spread the load over a larger surface area, reducing the chance of surface damage. They have tiny ridges under the head that bite into the part you’re fastening, keeping the joint tight even when the equipment vibrates. This extra grip is especially useful on thin metal brackets, engine parts and car frames that are constantly shaken by everyday use.

While flange bolt manufacturers prioritize simplified assembly and reduced part count, the main benefit of flange bolts lies in consistent clamping and vibration resistance during practical applications.

Manufacturers may need to stock fewer parts, and be able to finish assembly sooner since flange bolts don’t need an additional washer. Fewer parts mean reduced handling time, easier inventory management, and reduced risk of incorrect washer being selected during installation. These advantages make them especially suitable for high-volume production environments, where consistency and speed are of extreme importance.

At Fastener World (India), we keep flange bolts across a wide range of material grades, including:

– Mild Steel Grades 4.6 and 5.6

– Alloy Steel Grades 8.8, 10.9 and 12.9

– Stainless Steel Grades 202, 304, and 316

Key Differences

| Aspect | Hex Bolt | Flange Bolt |

| Built-in Washer | Does not have an integrated washer, requiring a separate washer for installation | Has an integrated washer, eliminating the need for a separate washer |

| Bearing Surface | Relatively narrow bearing surface | Wide bearing surface due to the built-in flange |

| Weight | Lighter since there is no integrated flange | Heavier due to the in-built flange |

| Vibration Hold | Needs a lock washer or spring washer to resist loosening | Serrated ridges help maintain grip and resist loosening |

| Parts Needed | Two separate components in bolt and washer | Only one component is needed, since washer is integrated |

| Assembly Consistency | Quality can vary depending upon washer selection and placement | Provides more consistent clamping since it’s one single unit |

| Common Applications | Structural steel, machinery and fabrication assemblies | Automotive assemblies, brackets, frames and sheet-metal structures |

Conclusion

Hex bolts offer additional versatility, offering engineers the option to couple them with various washer types to produce the necessary clamping force, load distribution, and vibration resistance. They are an ideal choice for structural assemblies, machinery and applications where design control is crucial.

Flange bolts on the other hand prioritise efficiency and consistency. Their design simplifies assembly, reduces part count, and gives better resistance to loosening in vibration prone environments. They are preferred in automotive and sheet metal applications.

Eventually, the decision boils down to whether the application benefits more from customisable hardware or one-piece convenience. Understanding these nuances ensures better joint performance, quicker assembly, and a longer service life.

At Fastener World (India), we stock both hex and flange bolts in multiple sizes, thread styles, and coating options, giving manufacturers and engineers the opportunity to select what’s best for their project.