Types of Fastener Coatings and Their Benefits Explained

Introduction

Since fasteners are routinely used across various industries, they find themselves being exposed to harsh environments like moisture, chemicals, temperature variations, and mechanical stress. These conditions are responsible for expediting the wear and tear, significantly reducing the lifespan and durability of fasteners. To counter this, a protective coating is applied, which not only allows them to deal with these conditions better, but also enhances the overall appearance and finish.

Armed with this information, manufacturers can accurately select fasteners that suit their project requirements, both from a performance and cost standpoint.

Coating Types

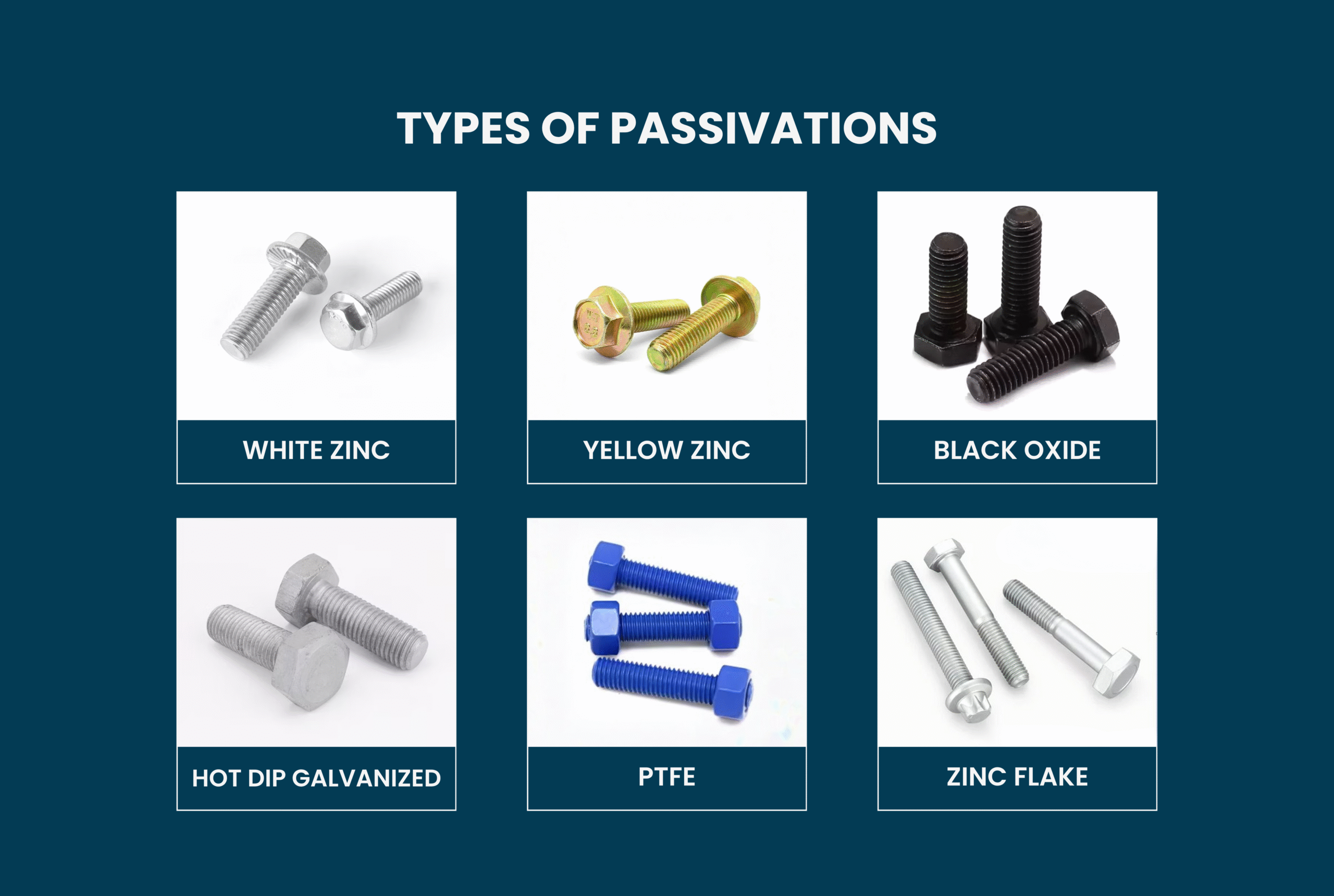

Zinc

Zinc is probably the most common coating applied to fasteners. This offers good resistance against corrosion at a relatively low cost, while also being available in multiple finishes such as white, yellow, and black to support the various needs of manufacturers.

White Zinc

This provides a clean, silver finish, which is best used for indoor or controlled environments.

Yellow Zinc

This coating provides slightly better corrosion resistance due to the chromate layer.

Black Zinc

This offers moderate corrosion protection with a matte finish.

These coatings tend to fall within the range of 120-240 hrs SST life.

Hot Dip Galvanizing

This involves dipping fasteners into molten zinc, thereby creating a thick, corrosion-resistant layer. This results in a rough, matte grey finish which offers great protection in outdoor environments, with the SST exceeding 1000+ hrs.

This coating is primarily used in construction and infrastructure applications.

Zinc Flake

Zinc Flake coatings are made of zinc and aluminium flakes, which are applied via dip-spin or a spray process. This type of coating offers high corrosion resistance, up to 1500 hrs SST, and it also does not cause hydrogen embrittlement, making it ideal for high-duty applications.

Black Oxide

This creates a dark, matte finish by chemically changing the surface of the fasteners. Despite improving the aesthetics, its ability to significantly improve corrosion resistance remains limited. This type of coating is best utilized for indoor applications or where appearance is highly valued.

Nickel

Nickel offers a bright, decorative finish with moderate corrosion resistance. This is typically used in electronic applications and consumer hardware where visual appeal is important.

Conclusion

The focus of manufacturers should not just be on selecting the right type of fastener, but also the most suitable coating to extend its service life. This also ensures that fasteners are capable of meeting various project-specific safety standards and guidelines.

At Fastener World (India), we offer a range of coating options that enhance the overall appearance of fasteners along with improving their performance and durability.